Sunole is an olefin based synthetic yarn which is durable to outdoor conditions. Due to the additives and special pigments used in the production, Sunole provides high protection to sun and weather conditions, high color fastness and very limited tenacity loss in the material.

The research and tests are continuing to ever improve the performance of Sunole.

Olefin as well as acrylic and polyester materials are being used for outdoor textile products and the usage of olefin is imcreasing and becoming more and more popular.

Olefin has got the following advantages compared to other materials:

- Specific density of olefin is 30-40% less

- Tenacity of olefin is 30-100% more

- Polymer properties of olefin is more flexible; flame retardancyiantibacterial property,dyeability during spinning

- Olefin can be recycled easily and is more environment friendly

- It is foreseen that Olefin will improve and expand in the markets in the years to come.

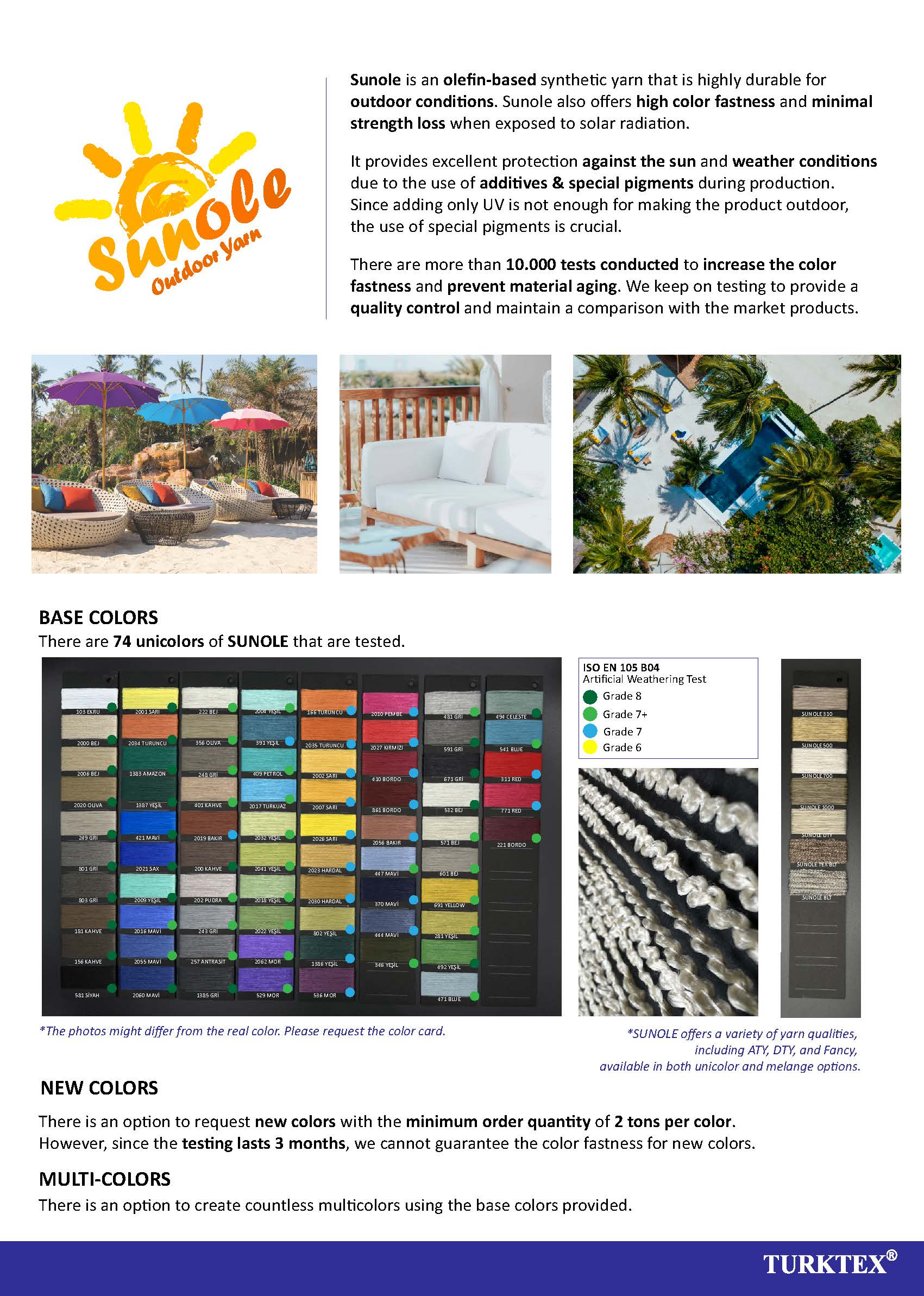

Sunole is offered with about 100 uni colors and thousands of multicolors.

The service is as fast as one week,thanks to the raw material stocks.

During development of Sunole long term laboratory tests and real life trials are conducted and a high standard outdoor product has been created.

Color fastness tests are conducted on “Atlas Xenon 440+” device according to BS EN ISO B04 standard. The tests are done until 2000 hours and the fastness values are reaching up to 5 as gray scale. For even red and orange like colors, high fastness values are reached.

A special UV stabilizer developed by Turktex is being used in Sunole products. The durability varies according to region, when used as outdoor upholstery product this can extend to 5 years.

Material strength tests are done on “Q-LAB- QUV” device according to ASTM G-154 standard. It is foreseen that Sunole can resist up to 3 years in regions like South France, Spain, Italy, Greece and Turkey.

Sunole is also superior to other fibers as it is the lightest fiber with a 0,94 gr/cm3 density.

Sunole outdoor yarns are used in the following applications:

- Garden and decoration furniture

- Hotel, Café outdoor products

- Boats, Yachts, Marine sector

- Beach and Pool products

Sunole yarns are taslanized, twisted dope dyed ranging from 300 to 2700 deniers.

Sunole products:

CF qualities;

- Uni colors between 150-600 denier

Air textured;

- SUNOLE Series between 300-2700 denier for uni and multi colors

- SUNOLE 300and 450 denier has twisted versions for uni colors

- SUNOLE 2000 and 2700 denier has degrade version

Developments and test phrases are continuing for Sunbed use.

Textured qualities;

- SUNOLE 150,300,450 and 600 denier for uni and multi colors

Fancy qualities;

- SUNOLE FNC Series between 900-4000 for uni and multi colors

- SUNOLE TPT Series between 670-10000 for uni and multi colors

As the test confirm Sunole is developed to be superior than its competitors and still being improved. Furthermore, the service of Sunole is much faster than competitors due to raw material stocks kept. These stock levels are calculated with statistical models. And the lead time is 1-2 weeks.

Service for Acrylic based products are limited and the delivery times are much longer. In addition to these, it is a fact that acrylic is not environment friendly therefore its consumption is decreasing year by year.

It is experienced that Sunole can resist over 5 seasons in regions such as Southern France. (around 140 kLangley per year)

![]()